|

CNC machine for metal work/rack panels |

Post Reply

|

Page 12> |

| Author | |

kevinmcdonough

Old Croc

Joined: 27 June 2005 Location: Glasgow Status: Offline Points: 3751 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Topic: CNC machine for metal work/rack panels Topic: CNC machine for metal work/rack panelsPosted: 20 August 2015 at 11:51am |

|

hey all

Hopefully working with someone on here just now who "has a guy" and can get me some rack panels sorted for the racks I'm building just now, but in the past this has always been a bit of a faff, always people who say they can sort it then drift away after an email or two and I'm left hanging. Ideally would like to get a machine so I can do it myself save having to rely on others. A CNC machine of some kind that could route/cut/punch the holes for the various connectors then engrave text below these to label them as needed. Not too fussed about what technology is used (routing/laser/plasma) but should be able to cut through a few mm of steel, unlike the cheap £300 or £400 ones one on ebay that seem to only do aluminium. Laser would be nice but I assume expensive, so normal routing would be OK too. Ideally I'd like to go about £1000 or not too much more, but just looking to see what all the options are really. Big enough to obviously do 19" in one direction, and maybe 3u or so would be enough for day to day work. If thats to hopeful, then even something to just do the engraving would be good, as getting panels punched on their own seems to be a bit easier and I can add the text after. Thoughts? Anyone got any links or anything they can send? Obviously if I get something sorted I'll be happy to look at doing panels and speaker connection plates etc for forum members as well  k

Edited by kevinmcdonough - 20 August 2015 at 12:10pm |

|

|

|

snowflake

Old Croc

Joined: 29 December 2004 Location: Bristol Status: Online Points: 3122 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 12:04pm Posted: 20 August 2015 at 12:04pm |

|

I would be interested in this as quotes from UK seem ridiculous - £88 to do a 1U panel! best quote I have got is from US and shipped over.

|

|

|

|

odc04r

Old Croc

Joined: 12 July 2006 Location: Sarfampton Status: Offline Points: 5482 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 12:14pm Posted: 20 August 2015 at 12:14pm |

|

Interesting topic, I'm halfway through building my own currently for a similar level of work (light metalwork down to PCB engraving) I'm guessing you are not interested in building your own? But do you want a one stop delivered solution, or would you be ok with some assembly? I'd certainly stick to routing for simplicity and safety. Would you like the mill to come with all s/w and a PC or would you supply that. Then there are the motors, motor drivers, and breakout board from PC. Like anything DIY you can save a lot by careful self building depending on the time vs money equation.

A lot of the cost could end up being software, but there are reasonably priced CAD packages out there such as Cambam which people seem to like. More of a concern is the s/w used to run the g-code that CAD produces. If you are going to buy a mill check what comes with it. For windows a lot of people seem to like Mach3 and the pricing is not too bad. There is also LinuxCNC which is free and quite powerful. It installs using its own distro so is pretty painless if you're not linux experienced, don't let that put you off trying it. You will need a PC with a parallel port to run it. I got it running my motors without too much drama but have yet to assemble the full frame and try a complete toolchain of design to cutting. Some more modern cnc's use USB breakout boards and I think mach3 supports a few output boards via it. So for future proofing that may be something to consider, who knows how long motherboards will continue to offer suitable parallel ports (these are the majority of home level CNCs). Something to think about is that if you use your own PC, laptops are generally bad and sometimes older is better. I had to do a bit of tweaking and basically force the CPU to constantly poll and not pwoersave before I could get good thread performance on a Dell 960 (Core duo so a bit old now). Modern processors have so much going on it can mess with real time output of gcode if setup is not done properly. This is where a breakout box that buffers gcode output rather then just directly controlling motors such as the smoothstepper can pay off in a modern system. So I guess to make any recommendations it would help to know if you want a total turnkey system or you are willing to do some bits yourself such as the PC end and just puchasing the mill + electronics. If you have the patience and go slow then there are always Ebay bargains out there. I bought second hand ballscrews, closed loop motors, broken Kress 1000 spendle (which I fixed) and I think when I am done I will be less than £1k for the whole system. But I got a lot of free and second hand parts which puts the total system cost of even a small mill in perspective. Another thing that would be helpful to define is what sort of feed rate and minimum dimension you would like to achieve, then work backwards from that in terms of motors and drivers. If you are willing to accept some backlash and play then you can save a lot of money on cheaper lead screws. One good quality ballscrew on its own can easily be >£100 with no problem. I think that you may struggle to get quality at £1k, most quotes I looked into years ago were £2k+ for good quality mills and that was usually without PC and software. Perhaps prices are a bit lower now, a lot of people buy the cheaper chinese mills and then set about improving them in various ways. Some even like them as they come. Check out http://www.cnczone.com/. There is a ridiculous amount of knowledge there, reviews of turnkey hobby systems etc etc. Like any engineer type community (cough, cough) some people can be a bit dickish but if you lurk and read a bit before stating what you're after I think you will get advice from some people who know their stuff. |

|

|

|

Twiggy

Registered User

Joined: 25 January 2012 Location: Portsmouth Status: Offline Points: 432 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 12:14pm Posted: 20 August 2015 at 12:14pm |

|

Sadly most machine shops will charge their £60ph + materials, etc no matter the simplicity of a job.

As for just punching holes in steel sheet is just look at fly press mate, old school but for small batches for yourself much easier. CNC mills are unsuitable for most sheet work, so need vaccum or mag beds, or need laser cutting which is well out of the realms of home use and affordability. What about 3D printer? Allow you to do a lot more creatively, even having cable cradles, embosed logos, etc *edits... About throw this stupid phone at the wall... Edited by Twiggy - 20 August 2015 at 12:19pm |

|

|

|

odc04r

Old Croc

Joined: 12 July 2006 Location: Sarfampton Status: Offline Points: 5482 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 12:16pm Posted: 20 August 2015 at 12:16pm |

Have you tried these dudes - http://www.schaeffer-ag.de/en/downloads/front_panel_designer/ Integrated CAD designer with upfront costs, did a couple of 1u panels with them and was about £80 for both +shipping a couple of years back. Costs can go up quick though if you start adding loads of cutouts and text. |

|

|

|

S&P

Registered User

Joined: 01 March 2008 Status: Offline Points: 222 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 12:42pm Posted: 20 August 2015 at 12:42pm |

|

Sounds and Pressure Lo Fi Sound - Ska, Rocksteady, Reggae

http://www.facebook.com/events/412323448834558/432237103509859/?comment_id=432362186830684¬if_t=event_mall_reply#!/groups/75371249167/ |

|

|

|

dylan-penguinmedia

Old Croc

Joined: 14 April 2011 Location: Brighton Status: Offline Points: 4575 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 1:31pm Posted: 20 August 2015 at 1:31pm |

|

Try Alan at Lincoln Binns, for custom rack panels, cut, printed, etc... Good prices too.

Say Dylan sent you :) Tel: 01403 865486 Email: Alan@lincolnbinns.com Web: www.lincolnbinns.com Web: www.panel-print.com |

|

|

|

turbo7

Registered User

Joined: 15 March 2009 Status: Offline Points: 233 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 3:23pm Posted: 20 August 2015 at 3:23pm |

|

i have just spent 4 times your budget and i am able to do light steel works with the most powerful machine you can find for this price... the spindle alone does cost you 200 min. and then it is a cheap china one, but works OK for LIGHT steel works. you need a high torque at low spindle speed for steel works, both the strenght of the gantry and the spindle will limit steel works in cheap systems

|

|

|

|

geoSal

Registered User

Joined: 05 July 2011 Location: THESSALONIKI Status: Offline Points: 338 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 5:27pm Posted: 20 August 2015 at 5:27pm |

|

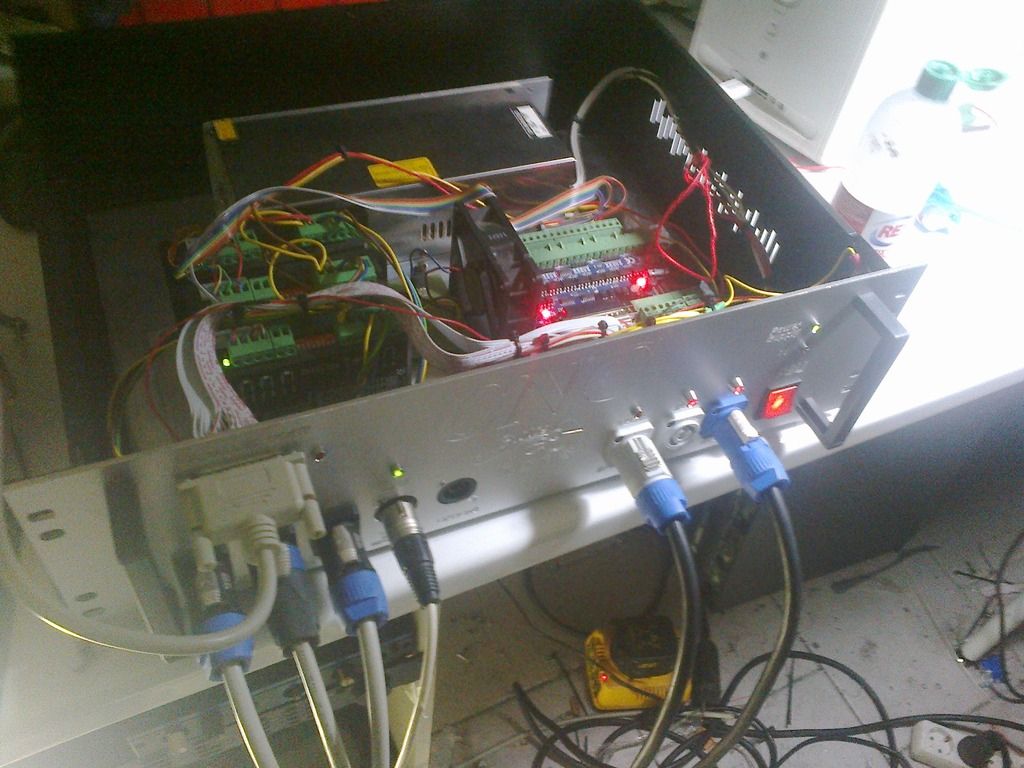

I 've bulilt a cnc router machine last year.dimensions are 100cmx100cm.Motors are nema234N and the spindle is a Kress fme1050.Except wood and plastic I also cut alluminum panels and recently tried on steel with very good results.Engraving on anodised allouminum is also possible.

It is built with high grade parts and materials.It is driven from Mach3 from artsoft.Rhino3d v5 is my CAD software and Aspire v8 from vectric is the CAM soft.I use an old desktop with parallel port which seems to be the safest and fastest way to run it.I only work cad/cam files from a laptop. The whole thing with routers has to do with bits and knifes.Choosing the right one for the right job and run in the correct speed is essential for a good result. Pcb boards is also an easy task after designing it with eagle and aspire.Bits that we use for pcb's are 0.4-0.8mm end mills and 20degrees v-bits. some old pics and projects                  |

|

|

|

MarjanM

Old Croc

Joined: 10 February 2005 Location: Macedonia Status: Offline Points: 7816 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 10:12pm Posted: 20 August 2015 at 10:12pm |

|

What was the cost to build that cnc? I need one in just that size 1x1m.

|

|

|

Marjan Milosevic

MM-Acoustics www.mm-acoustics.com https://www.facebook.com/pages/MM-Acoustics/608901282527713 |

|

|

|

dlyxover

Old Croc

Joined: 14 June 2007 Location: Liverpool Status: Offline Points: 1502 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 20 August 2015 at 10:17pm Posted: 20 August 2015 at 10:17pm |

|

Not sure if the would be suitable.

|

|

|

In the Truth there is no news, and in the News there is no truth

|

|

|

|

geoSal

Registered User

Joined: 05 July 2011 Location: THESSALONIKI Status: Offline Points: 338 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 21 August 2015 at 12:23am Posted: 21 August 2015 at 12:23am |

around 2000euros.not exactly sure cause the parts where bought in different periods. Although it could cost much less if electric parts where purchased from e-bay. |

|

|

|

Post Reply

|

Page 12> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |