|

Djyves Projects CB(X)-18's, TH-SPUD, Duran, CNC |

Post Reply

|

Page <1 33343536> |

| Author | |

Tigersonics

Registered User

Joined: 17 August 2014 Location: Stockport, UK Status: Offline Points: 12 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 October 2014 at 8:42pm Posted: 24 October 2014 at 8:42pm |

|

Mmmmm, tasty looking! I've been following this thread, loved it!

|

|

|

|

Teunos

Old Croc

Joined: 23 November 2008 Location: The Netherlands Status: Offline Points: 1799 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 24 October 2014 at 8:53pm Posted: 24 October 2014 at 8:53pm |

|

how do you do angled cuts? By stepping the depth on every pass, or just cutting it later on a tabelsaw?

|

|

|

Best regards,

Teun. |

|

|

|

Audio_Stash

Registered User

Joined: 02 June 2014 Location: UK Status: Offline Points: 245 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 October 2014 at 12:19am Posted: 25 October 2014 at 12:19am |

Most guys take it to the table saw to do the mitre cuts

|

|

|

|

djyves

Young Croc

Joined: 06 April 2009 Location: the Netherlands Status: Offline Points: 564 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 25 October 2014 at 12:20am Posted: 25 October 2014 at 12:20am |

|

Thanks, always good to follow this thread, haha.

I'll keep you updated. Making angled cut's on the cnc does work, but it's a time consuming process. Right now my X-axis isn't very fast, only 3m/min. For making angled cut's a bit more speed would be nice, I'm working on it. At a cutting speed of 2m/min, the cutting of the flightcase took about 45 minutes. If I had done all the speaker panels in one run it would have taken about 95 minutes to cut everything, except the angles. For these speaker panels I used a Festool plunge saw to cut the angles. I'm planning on buying some different sizes of v-bit's to cut angles. Edited by djyves - 25 October 2014 at 12:21am |

|

|

"If brute force doesn't work, you're just not using enough!"

|

|

|

|

djyves

Young Croc

Joined: 06 April 2009 Location: the Netherlands Status: Offline Points: 564 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 02 November 2014 at 11:26pm Posted: 02 November 2014 at 11:26pm |

|

Made and spray painted the doghouse for the mixer case:

Also spray painted the 12'' speakers:  Letters came out nice:   |

|

|

"If brute force doesn't work, you're just not using enough!"

|

|

|

|

hond

Young Croc

Joined: 10 October 2009 Location: Louvain BEL Status: Offline Points: 619 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 03 November 2014 at 1:13pm Posted: 03 November 2014 at 1:13pm |

|

damn impressive.

|

|

|

|

geoSal

Registered User

Joined: 05 July 2011 Location: THESSALONIKI Status: Offline Points: 338 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 November 2014 at 7:39pm Posted: 17 November 2014 at 7:39pm |

|

I thought I would post this here..

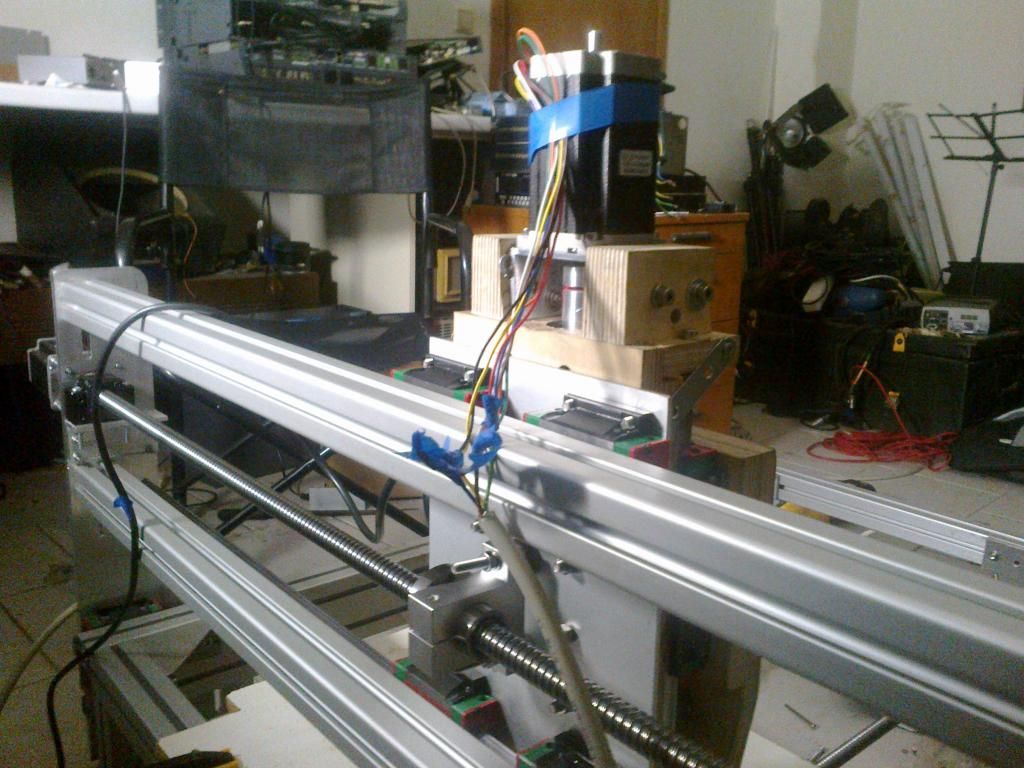

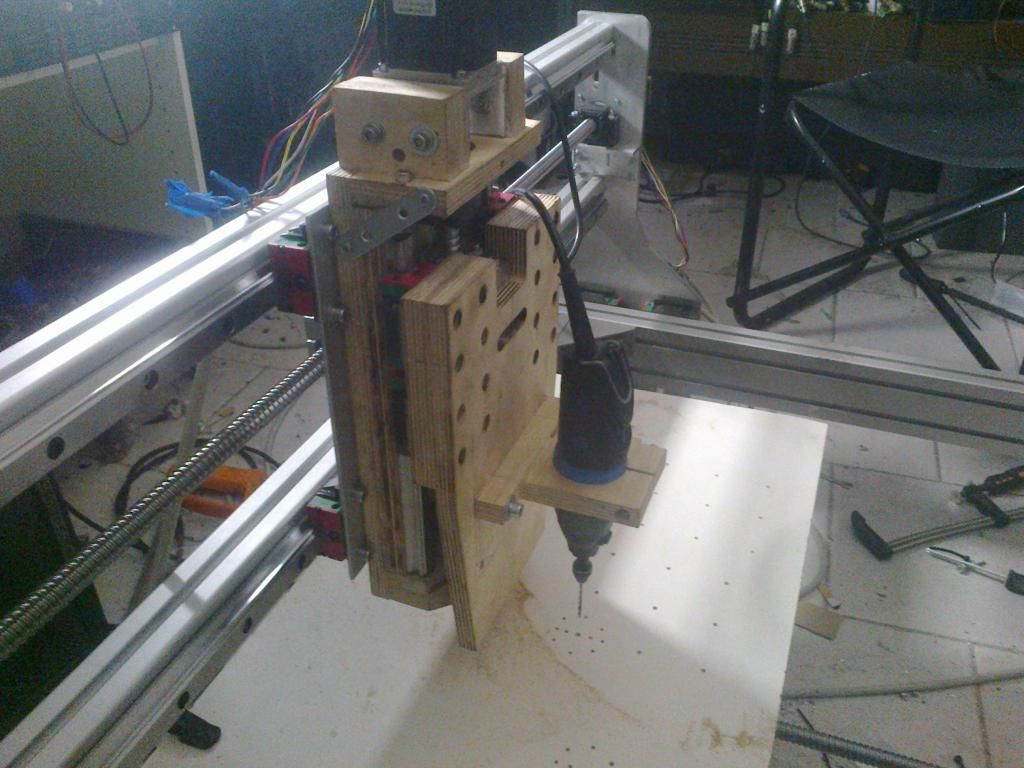

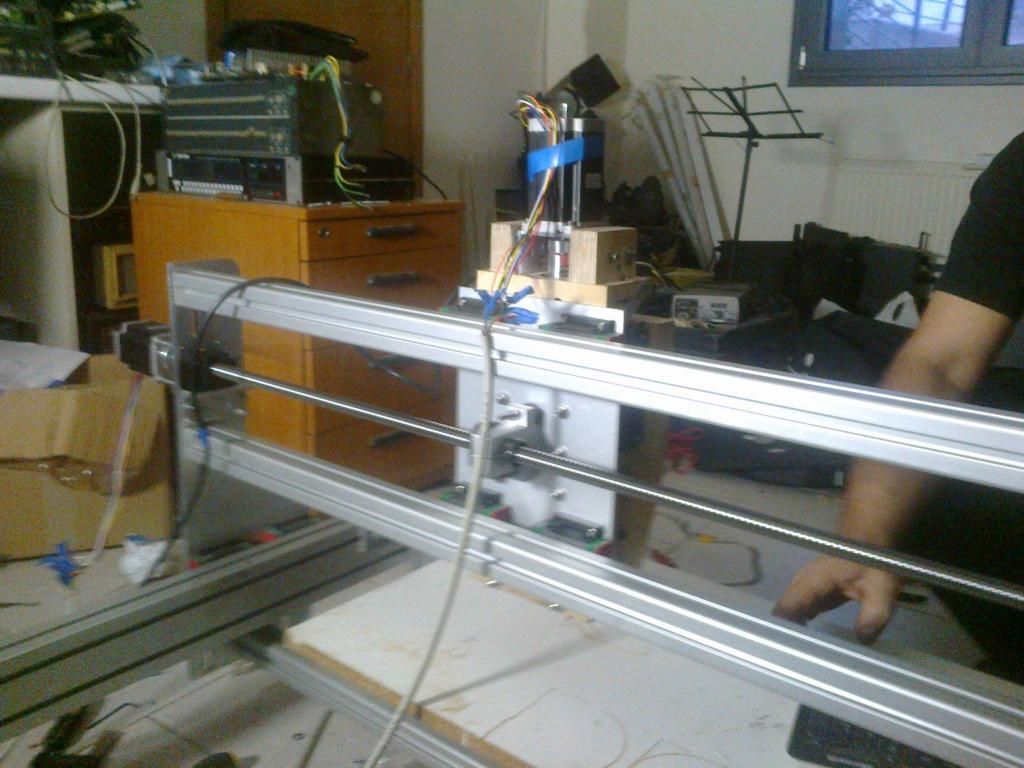

First CNC moves.The z axis is temporarily made from wood in order to cut an alluminum one when the CNC is ready.The small dremel is also for testing purposes till the Kress spindle arrives. Built for small to medium sized speakers and alluminium parts. These are the first motor and tuning tests.Sorry for the bad photos..        |

|

|

|

MarjanM

Old Croc

Joined: 10 February 2005 Location: Macedonia Status: Offline Points: 7816 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 17 November 2014 at 8:15pm Posted: 17 November 2014 at 8:15pm |

|

Looking good :-)

|

|

|

Marjan Milosevic

MM-Acoustics www.mm-acoustics.com https://www.facebook.com/pages/MM-Acoustics/608901282527713 |

|

|

|

djyves

Young Croc

Joined: 06 April 2009 Location: the Netherlands Status: Offline Points: 564 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 December 2014 at 11:58am Posted: 11 December 2014 at 11:58am |

|

Decent

size, you can still build some boxes with that.

At the moment, my

own cnc is not yet finished, but I have started on another one. Not for myself,

for in a workshop.

This one is made

out of 18mm birch ply. 5m wide, almost 2,5m

high.

Rack and pinion

for X and Y, Z had a 16mm ballscrew with a pitch of 10mm. Nema 34 11,2Nm

motors are used.

A few

pictures, Construction of

the frame:

The machine in its

final position. The spoil board will be replaced by mdf or birch plywood:

1.5Kw spindle with

auto tool changer:

|

|

|

"If brute force doesn't work, you're just not using enough!"

|

|

|

|

Timebomb

Old Croc

Joined: 11 October 2004 Location: Lancaster Status: Offline Points: 2717 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 11 December 2014 at 5:05pm Posted: 11 December 2014 at 5:05pm |

|

That looks ace Djyves!!

Is the frame fixed to the floor and wall? Are you running direct drive on the X or is there some reduction? Im considering gearing mine as im missing steps, i need to eliminate a few other things first though. Where did you get the tool changer? |

|

|

James Secker facebook.com/soundgearuk

James@soundgear.co.uk www.soundgear.co.uk |

|

|

|

djyves

Young Croc

Joined: 06 April 2009 Location: the Netherlands Status: Offline Points: 564 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 December 2014 at 11:24am Posted: 12 December 2014 at 11:24am |

|

Frame is fixed to the wall.

I'm goint to try direct drive this saturday, if it doesn't work out I'll try some reduction. What sort of motors do you use? The tool changer comes from some russian webshop, I'll look it up.

|

|

|

"If brute force doesn't work, you're just not using enough!"

|

|

|

|

Timebomb

Old Croc

Joined: 11 October 2004 Location: Lancaster Status: Offline Points: 2717 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 12 December 2014 at 3:40pm Posted: 12 December 2014 at 3:40pm |

|

Cheers yeah id be interested in a tool changer that didnt cost loads. Im only using 3.1Nm steppers with 1/8th micro stepping. So i think you should be fine for torque. Ive been having issues with the pinion slipping, i just tightened them up again (and snapped the head of a M3 cap head screw) so hopefully it will be ok now. I dont know if its an issue due to backlash or stiction from running direct, there dosent seem to be many people doing it, plenty are doing it with geared steppers though.

Heres a little vid of my machine i made to for the guy at cnc4you to see what he recons on my motor tuning. https://www.facebook.com/video.php?v=10152969974815229&pnref=story |

|

|

James Secker facebook.com/soundgearuk

James@soundgear.co.uk www.soundgear.co.uk |

|

|

|

Post Reply

|

Page <1 33343536> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |